INTECSEA and Innospection team up to launch FlexIQ - a comprehensive flexible riser integrity management program

HOUSTON (June 29, 2016) - INTECSEA and Innospection Ltd announced today the launch of FlexIQ, a complete offering in the arena of flexible riser integrity management from the strategic alliance between INTECSEA and Innospection.

This partnership redefines the approach to flexible riser integrity management by offering clients best in class inspection and computational simulation techniques as part of an overall Integrity Management Framework. In turn, this leads to a significant improvement in understanding of operational risk and enables a fully integrated service for inspection, analysis, and data management.

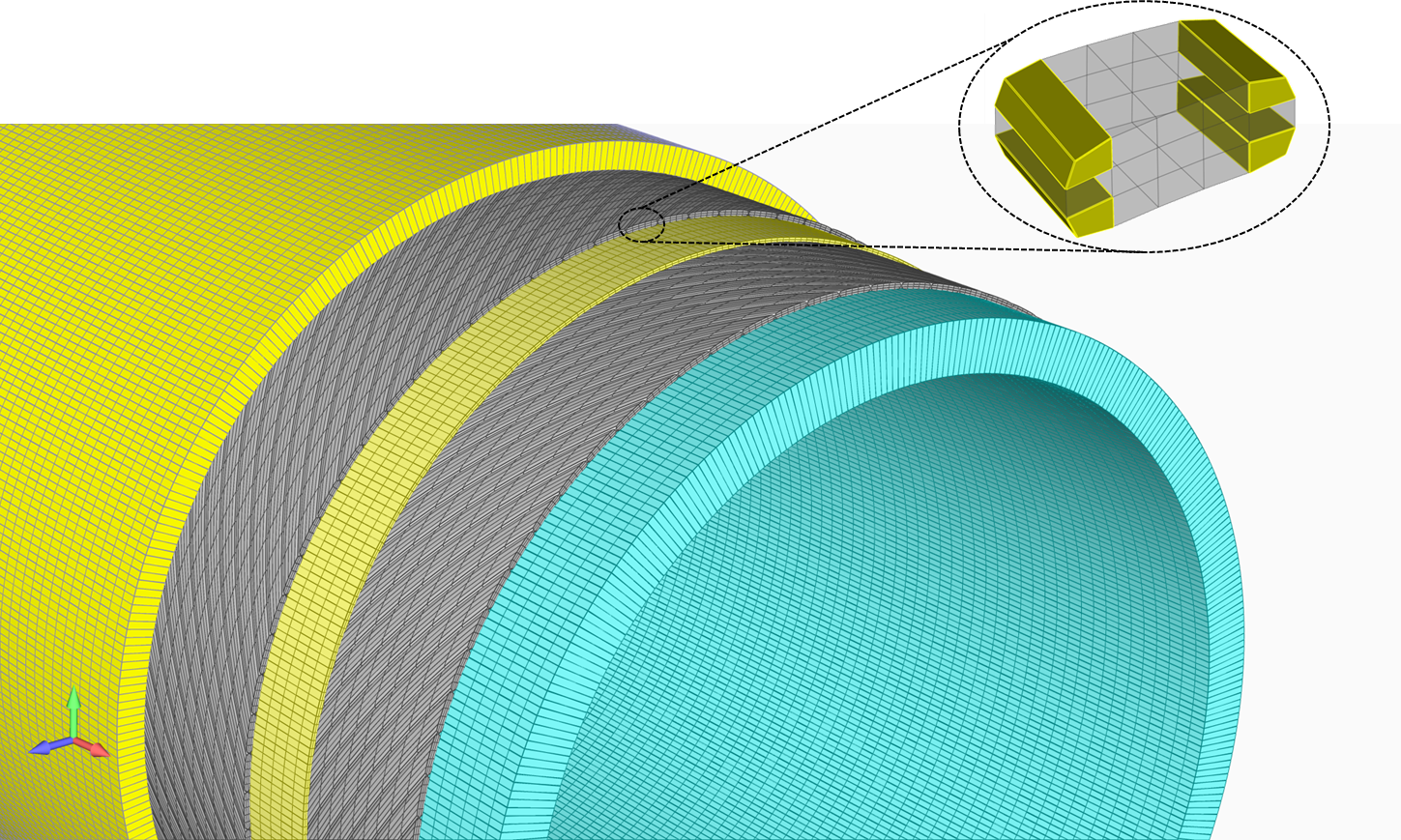

Central to the value and distinctiveness of FlexIQ are the state-of-the-art and proprietary inspection capabilities of MEC-FIT™ and numerical simulation capabilities of FLEXAS™. MEC-FIT™ inspection combines DC magnetic and Eddy Current fields to detect damage in up to three metallic layers, including cracking, pitting, and general corrosion, as well as wire misalignment and gaps, all without requiring the riser annulus to be flooded. This unparalleled level of inspection data is then incorporated into high fidelity 3D finite element models for simulation with FLEXAS™, a multi-body nonlinear dynamic substructuring solver. FLEXAS™ conquers the computational limitations of other industry simulation software, resulting in high resolution fatigue spectra and accurate fatigue life predictions.

By combining these capabilities with industry-leading annulus testing and a formal risk-based approach to flexible riser risk assessment and life extension, FlexIQ delivers all aspects of flexible integrity management through a single provider.

Commenting on the partnership with Innospection and the FlexIQ offering, INTECSEA president Neil Mackintosh said, “Innospection is a perfect partner for INTECSEA in the offshore inspection space. We feel the alliance is a natural extension of our mission to provide innovative, independent solutions across the project lifecycle. We are confident our advanced FLEXAS™ technology, combined with the unparalleled inspection capability of Innospection, will provide increased understanding, and reduced uncertainty and cost for clients in the arena of flexible risers. The bottom line is that FlexIQ delivers insight, not just data.”

Andreas Boenisch, Managing Director of Innospection said, “In decades of industry experience, with the majority in offshore asset inspection and integrity assessment, I have found the complexity of flexible risers to be unique. Reliable integrity assessment and remaining life evaluations of flexibles require focused and advanced technology and innovation, combined with expertise.

At both Innospection and INTECSEA, these attributes are present. The resulting combination of capabilities is FlexIQ, which provides operators of flexible risers the unique opportunity to work with a partner capable of providing the absolute best possible data and analysis.”

For more information on FlexIQ, visit http://www.intecsea.com/project-delivery/asset-management-brownfield/flexiq.

About INTECSEA

INTECSEA offers independent insight, engineering and project management to deliver full lifecycle asset management, in any offshore environment from concept to decommissioning.

Backed by extensive technical expertise, INTECSEA people work with clients to turn complex challenges into practical results. Bringing real insight to support critical business decision making, their imagination can reveal unseen options. And they can help you choose solutions from all appropriate sources.

With the full capability of Advisian and the wider WorleyParsons Group readily available, INTECSEA is the obvious choice. A leader, not a follower, committed to delivering value by collaborating with clients as well as competitors, INTECSEA’s independence of thought and action is clearly the informed choice for offshore infrastructure projects now and in the future.

About Innospection

Innospection Ltd is a specialist provider of advanced and innovative inspection services and solutions for the integrity and lifetime assessment support of topside, splash zone and subsea assets.

An expert in electromagnetic inspection technologies such as Eddy Current and Magnetic Eddy Current (MEC) which is a further development of the fast corrosion screening SLOFEC™ technique, Innospection has delivered advanced non-destructive testing services to the worldwide process industries including the oil and gas industry (onshore and offshore), refineries, petrochemical and power plants since 1998. Innospection’s inspection technologies are used worldwide as key tools for lifetime extension and fitness-for-service assessments.

With experienced inspection engineers and an innovative R&D team, Innospection has created an enviable reputation for applied expertise, quality and effective delivery within the industry.

Visit the company’s website at www.innospection.com, or connect with Innospection on LinkedIn.

We are excited to announce that

We are excited to announce that